Founded in 1984 in Brindisi with the activity of gas turbine overhaul and machining, Avioman is an engineering company that today produces structural mechanical components and assemblies mainly for rotary and fixed-wing aircrafts.

In 1999, it started the design, production, maintenance, overhaul and delivering of AGE equipment.

In 2006, the company strengthened its CAM programming skills, expanded its machine pool and focused on precision mechanics.

With a view to transparency, monitorability and growth aimed at supplying an increasingly complete and competitive product, Avioman placed process digitisation at the hearth of its development plans.

Mission

Vision

Acting with strong ethics is a priority for all those representing the organization and this approach guides the behavior of the company as a whole.

Accepting responsibility for our actions is the best way to build trust inside and outside the company.

We take pride in shaping the company with commitment and dedication to continuous improvement by leveraging on internal and external inputs to deliver high quality products and increase customers’ satisfaction.

Values

Our Expertise

DESIGN AND 3D MODELING

3D modelling and design, for which we use Catia V5 software.

Main activities: product concept elaboration and definition, solid and surface 3D modelling, drawing and drafting.

INDUSTRIALIZATION

We industrialise the product with the objective to comply with our customers’ technical

requirements while maintaining the highest quality standards.

Main activities:

work cycles and bill of materials processing, production process optimisation.

NC MILLING

We perform mechanical machining of small and medium-sized flight parts on 3-, 4- and 5-axis machining centers with a maximum size of 2.5 x 2.2 x 1.1 meters.

TURNING

We perform mechanical turning machining of small and medium-sized parts on 3- and 6-axis lathes.

We design and maintain cryogenic equipment.

We carry out assemblies of subassys and small to medium-sized mechanical kits, e.g., helicopters’ pilot and passenger door locks.

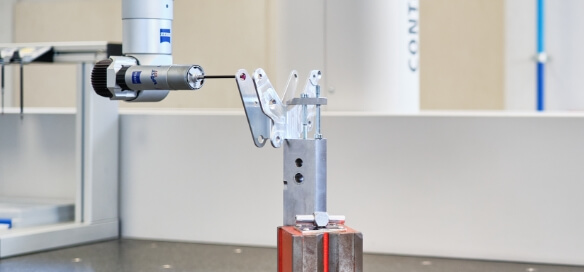

We carry out dimensional checks of mechanical parts using measuring machines.

We manufacture and design small-sized aluminum bonding and trimming tools according to customer specifications and tolerances.

Our History

Avionman s.r.l. was founded with the start-up of SOLAR T-62T-32 gas turbine overhaul activities, and related mechanical machining for ALFA ROMEO AVIO

1984

The Ministry of Defence gives Avioman the AQAP-4 NATO award for overhaul, repair and maintenance of aspirated and compressed reciprocating aircraft engines. Construction of special equipment for aircraft maintenance and repair shops as well as various parts and accessories for aircraft engines

1988

Qualified as Elicotteri Meridionali (Agusta group) supplier, obtaining NATO AQAP-4 certificate for mechanical machining, overhaul and related processes

1992

Intensification of the overhaul and repair of auxiliary gas turbines, hydraulic pumps and engines and AGE equipment for the Ministry of Defence and the Brindisi Naval Arsenal

1993

Acquisition of FIAT AVIO supplier qualification for parts refurbishment (seals, blades, vanes, AP turbine protection rings) for engines T64, J79 and Turbo-Union RB199

1997

Initiating the process of know-how diversification with the design, production, maintenance and overhaul AGE equipment such as liquid oxygen samplers, mobile units and liquid oxygen tank reclamation trolleys

1999

Started the production of lock kits for AgustaWestland helicopters (now Leonardo Helicopters Division) and in particular for AW109, AW169 and AW189 programs.

2006

Qualification as a supplier for Alenia Aermacchi, for machining parts of the M346 program

2010

Obtained qualification for Salver with start of production of most of Bombardier's C-Series Inboard and Outboard Flap machined parts

2015

Start of manufacturing process digitalization and new investment plan

2021

Expansion of portfolio with acquisition of new orders for rotary wing machined parts

2023